The proportion of renewable energies from solar, wind and water is rising continuously. However, sufficient storage options are of the essence to use these energies as efficiently as possible, for example in the event of surplus supplies. GKN Hydrogen in Pfalzen, Italy offers a particularly compact and safe option, low-pressure metal hydride hydrogen storage system with PC-based control from Beckhoff.

“The energy transition will be very difficult to achieve without sustainable energy that can be stored in the long term,” says Gottfried Rier, CTO of GKN Hydrogen. He adds that this is particularly true given that the global energy demand will continue to rise in the future. To rely consistently on renewable energies, sufficient storage options are essential for balancing out non-continuous power generation from sources such as photovoltaics and wind. He goes on to explain that hydrogen storage technology is very well suited as a buffer process: “Hydrogen produced from renewable energy sources is completely carbon-neutral and can be used at various levels, either directly as a fuel or as electricity via fuel cells. Particularly with the low-pressure process we use, hydrogen is also easy to transport and can therefore be consumed in a decentralised manner. What’s more, hydrogen has 2,7 times the energy content of fossil fuels and, in the form of metal hydride, it can be stored in both a very compact and safe way.”

Metal hydride storage offers multiple uses

GKN Hydrogen has developed technology which can charge and discharge hydrogen from specially prepared metal hydride several thousand times, without losing any storage capacity. Another advantage, particularly when compared to battery-based systems, is the long storage time. Hydrogen can be stored for years without loss. In concrete terms, GKN Hydrogen has developed three storage systems: HY2MINI (up to 25 kg of hydrogen, 420 kWh of electrical storage capacity),H2YMEDI

The metal hydride only needs to be heated to 20 to 30°C for optimum absorption of the hydrogen, while a temperature of 60 to 90°C is required to release the hydrogen.

Daniel Schwingshackl from Advanced Engineering at GKN Hydrogen, adds: “Our process offers another major advantage − it requires very little pressure. Our solutions work in the low-pressure range up to a maximum of 40 bar. In contrast to a gas tank, they require 15 times less volume and are significantly less dangerous compared to the tanks in hydrogen vehicles with pressures up to 700 bar.” Another safety aspect is that around 96% of the hydrogen forms a connection with the metal hydride – only 4% of it is volatile. In addition, recycled material can be used to produce the systems sustainably, and the low pressure does not limit the permitted material usage time.

Changing controls for greater flexibility

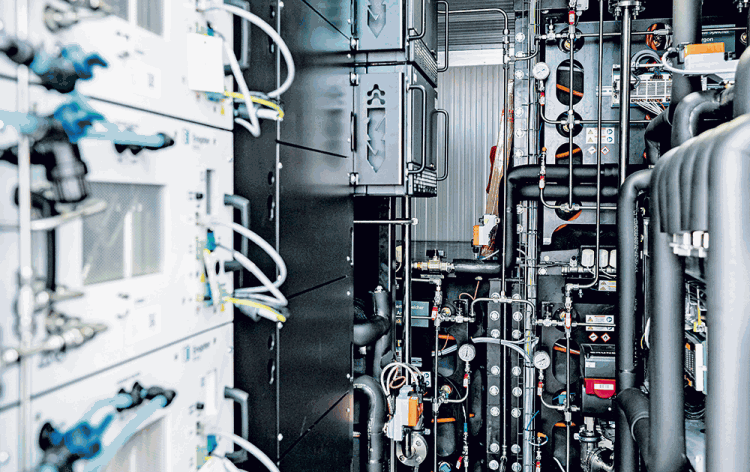

The sophisticated process sequences and the evaluation of about 150 sensors calls for a powerful, yet extremely flexible and easily scalable control technology. In 2021, these requirements ultimately led to the company switching from the previous conventional PLC control technology to PC-based control from Beckhoff. Roland Hilber from Electrical and Software Engineering at GKN Hydrogen, explains: “The Beckhoff control technology offered decisive advantages in terms of excellent scalability toward higher computing power and overall handling. The system is also both open and modular. The wide range of I/O terminals enables us to integrate a wide variety of components, ranging from a wide range of sensor technology and other essential third-party devices, to the system components for connection such as fuel cells and electrolysers. And let’s not forget all the advantages we gained from Beckhoff Austria’s fast and highly competent support. This is a particularly important aspect when we’re considering future projects.”

At first glance, the high precision and speed of PC and EtherCAT-based control technology from Beckhoff does not always appear to be necessary in the process technology environment. For Schwingshackl, however, it is very important. “Highly precise control will be of great importance in the future when our customers have to supply energy to the exchange and this has to be implemented precisely in terms of time,” he says. Hilber adds: “For this to happen, the energy acquisition and evaluation process needs to be as precise as possible. We can achieve this using the EL3443 and EL3446 energy measurement terminals and the distributed power measurement concept from Beckhoff.”

Additional data included in system control includes the temperature and pressure of the fuel cell or the load status, which is determined indirectly using the temperature and pressure. All this information is used to manage the entire energy flow efficiently.

The control system’s core is the C6015 ultra-compact Industrial PC, which for Hilber offers the advantage of energy efficiency packed into a compact design. “Especially when our storage systems are operating in isolated mode, every watt that is required for system operation counts because it is then not available for actual use,” he says.

A CP2916 multi-touch Control Panel is used for operation. According to Hilber, it was chosen for its appealing design and the excellent value for money it offers. In addition, GKN Hydrogen is also implementing TwinCAT HMI for visualisation, which easily enables operators to use their own controls.

Efficient use of I/Os and software

In addition to the diversity and modularity of the Beckhoff I/O system – which extends to the ELX terminals and the corresponding explosion protection expertise – GKN Hydrogen focuses primarily on the underlying EtherCAT communication. As the most important advantages, Hilber cites the plug-and-play nature of the EtherCAT components, the automatic device detection during network expansions, and the overall extremely stable network operation.

GKN Hydrogen also benefits from the measurement technology integrated into the PC-based control system. This starts with the SCT series current transformers, which easily replaced the previous transformers, and were just as straightforward to put into operation. The EtherCAT energy measurement terminals are used to record the power consumption of the entire system in detail – to detect anomalies or harmonics, for example. Data on the internal performance of individual devices or loads helps to optimise the process, and when designing new developments by identifying sub-optimal operating points or oversizing. This is also where the concept of distributed power measurement with the EL3443 and EL3446 energy measurement terminals shows its true strength – it offers a particularly efficient and inexpensive way of obtaining exact power measurement data, even in more sophisticated systems.

A key feature here is that all relevant electrical data from the supply grid, including real measured values for power, can be determined with the EL3446 as a mere current measurement terminal. However, the EL3446 terminals distributed in the system receive the voltage values required for calculating the power data via EtherCAT from a separate EL3443 power measurement terminal, which needs to be installed only once per network, and is precisely synchronised in time by the distributed clocks function in EtherCAT. This minimises hardware and installation costs.

According to Hilber, the system’s efficiency has also been demonstrated in the use of TwinCAT. “The integration of TwinCAT in Visual Studio is greatly beneficial, because many of our experts stem from this area and are used to high-level languages. The logical structure of both the software and the control projects makes it very easy to find your way around TwinCAT,” he says. In addition, the company also opted for TwinCAT Scope View, which enables simple evaluation of the relevant data – even over several days if required. In other words, all paths are open to GKN Hydrogen due to the connectivity provided by TwinCAT – primarily OPC UA and MQTT for IoT data transfer.

Versatile application options

The wide range of applications for GKN Hydrogen’s hydrogen storage systems extends from wind turbines and systemically relevant infrastructure to industrial plants, hospitals and apartment buildings. A prime example is the sustainable energy supply for the Müllerhütte cabin in South Tyrol which lies at an altitude of 3145 metres, and is only open in summer. The operators were looking for an alternative solution to a defective wind turbine and an outdated diesel generator. The company was able to implement the HY2MEDI hydrogen storage system

| Tel: | +27 11 795 2898 |

| Fax: | 086 603 6868 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved