At the Mercedes Technology Centre (MTC) plant in Sindelfingen, Germany, car axles are examined with the highest precision on four test benches, in parallel with road tests and simulations. The aim is to validate processes, analyse any anomalies specific to vehicles, and identify the components causing them. To do this, the developers measure the reactions of the vehicles when forces/displacements and torques are applied with high precision and in a reproducible manner. This allows the suspension, kinematics, and elastokinematics of the chassis to be recorded quickly and reliably. In addition, this data can be described objectively in the form of characteristic diagrams, characteristic curves and characteristic data sets.

Approximately 90 parameters are then compared with the digital twins of the vehicles. This protects both the development vehicle prototypes and the digital development process in that important area known as the Mercedes-Benz driving characteristics. “That’s why the test benches are an integral part of the Mercedes-Benz vehicle development process, where we ensure that parameters such as the component design, simulations, test benches, and road work together in harmony,” says Uwe Lochner, a member of the chassis analysis team at Mercedes-Benz in Sindelfingen.

To examine the chassis, the vehicle is set up on the test bench using the front axle jacks, then positioned and fixed over the four hydraulic jacks. The vehicle axles are then loaded and measured very precisely. “When we talk about precision, we mean measuring distances with 0,1 mm and angles at 0,1°, and less than 2 Hz with high sampling rates,” explains Walter Selg, managing director of DynoTec Prüfstandstechnik, the system integrator responsible for designing and implementing the retrofits. During the excitation process, a large number of sensors register the displacements, angles, forces, and torques. All data is acquired using PC-based control from Beckhoff, displayed live on a monitor at the test bench for the operator, and forwarded in parallel to a database system. “After the test run, all measured values are automatically processed and any limit violations are displayed in the results,” adds Selg. Using these results, Lochner and his colleagues determine whether they will release the vehicle for further testing, or whether the vehicle requires further analyses or any mechanical modifications.

Retrofitting in several stages

Using a signal processing component developed by Daimler, the Hydromat, selected parts of the test benches were repeatedly updated. The Hydromat is a modular control system for sophisticated test benches with setpoint input, measured value processing, output stages, and monitoring functions. Back in the early 2000s, the control functionality for the test benches was outsourced to an RCP rapid control prototyping (RCP) system from dSpace. After internal development for the remaining Hydromat functions was discontinued and it became as difficult to procure spare parts as with the control systems used to date, Mercedes-Benz commissioned DynoTec to design and implement an integrated automation solution for the test benches. There was one central premise for modernisation, retaining the modular concept of the test benches.

“Our first approach was to find a series product on the market that featured as many Hydromat functions as possible,” explains Lochner. In addition, they needed to replace the analogue signal lines, which measured up to 30 metres in length. “We didn’t find a series product to replace Hydromat, but we did find a promising open automation platform and ecosystem consisting of EtherCAT terminals, controls and a development environment at Beckhoff,” explains Lochner, recalling a visit to a trade fair. Another important criterion was the open nature of the EtherCAT protocol. This meant that they would not have to rely solely on Beckhoff for the components. There was also an EtherCAT interface to the RCP system.

Rainer Fischer, managing director of DynoTec, explains: “This gave us the opportunity to implement a test bench concept providing decentralised data logging and digital measurement signal transmission, with all possible advantages in terms of wiring and signal quality.” When it came to verifying and validating this concept, DynoTec examined a number of issues:

• What is the ideal coupling method to integrate the RCP system (synchronous/asynchronous, master to slave, slave to slave, or distributed clocks)?

• How does the signal quality of AD/DA converters from different manufacturers compare to the current system?

• Which RCP system task runtimes result from the configurations?

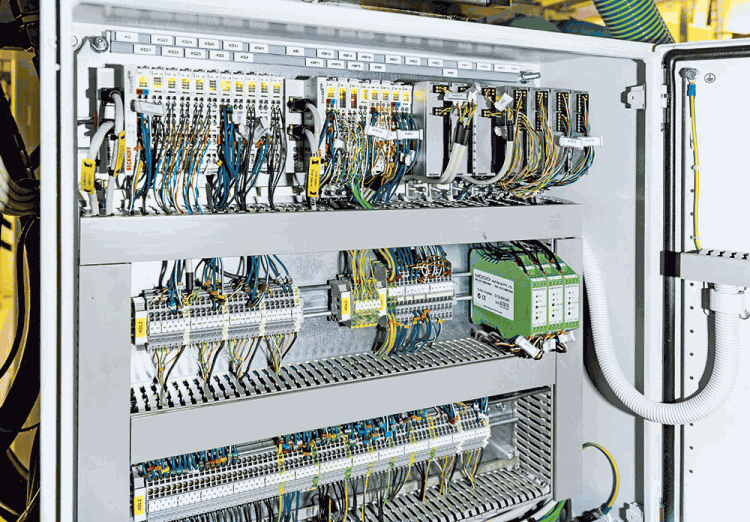

The outdated, traditional, and centrally arranged PLC technology has now been replaced by decentralised control cabinets with EtherCAT terminals mounted on the four jacks. The control cabinets contain the components for measured value acquisition and servo valve control for adjusting the jacks in the x, y and z direction, and for rotating them around the z axis. The PLC task and the associated HMI run on a CX5140 Embedded PC. The high-performance hardware allows the system status and error history to be visualised in detail on a CP2219 multi-touch built-in Panel PC.

The measurements are performed and visualised on a C5240 48 cm slide-in industrial PC. TwinCAT 3 HMI Server (TF2000) software supports the visualisation functions. All computers in the test benches are linked to a higher-level operating computer via TwinCAT ADS. In the overall system, the Beckhoff control system acts as the master and triggers the RCP system via UDP communication to achieve a high level of time precision and control quality.

High resolution and sampling rates

The decisive factors for DynoTec and Mercedes-Benz were the high sampling rates offered by the ELM3xxx measurement terminals, the high speed of data transmission via EtherCAT, and the simple, compact and modular data logging directly on the four hydraulic jacks. “All in all, our standardised system technology integrating classic PLC tasks and sophisticated measurement technology ensures a significant cost advantage,” summarises Fischer. “This is true even when dealing with the high bandwidth and resolution requirements that test benches place on the measurement technology,” adds Dieter Völkle, who is responsible for the project at the Beckhoff branch in Balingen, Germany.

During a test run, the system synchronously records up to 136 measurement channels at 5 ksps each (10 ksps optional). This corresponds to a total sampling rate of 680 ksps. In addition, there are 36 setpoint or output channels with 5 ksps each and around 300 channels with post-mortem diagnostic data, which are recorded at 100 sps. There is also a measuring box for external signals on each test bench. Each box has 16 analogue inputs for special measurement technology and 16 analogue outputs. These outputs can provide any measurement channel to record the outputs synchronously with the measurement technology installed in the vehicle, for example.

Space and time are always scarce on the test bench

The compact EtherCAT Terminals make it easier to log signals and reduce the space required. The control cabinets are now much clearer, facilitating rapid troubleshooting and fault rectification. “What’s more, we were able to save one out of five computer control cabinets on the test bench,” adds Lochner. In addition to space, the time factor is at least as important when it comes to testing vehicles. Here too, the modular system structure of PC-based control offers a distinctive advantage. Due to the repetition effect, the process of converting the other test benches was much quicker. “Compared to the first test bench, we were able to reduce the downtime by more than 30% when converting the last test bench,” says Fischer from DynoTec.

Given that use of the TwinCAT Analytics Logger is planned as the next expansion stage, the measurement data from the four test benches can be conveniently accessed for post-processing in the future. The real-time data logger is easy to configure, and streams all measurement data to a central storage location.This also simplifies post-processing across all test benches. With TwinCAT Analytics, it is possible to analyse both the historicised data and the live measurement data online.

For test bench specialist DynoTec, this project, with its extremely demanding measurement technology and control tasks, has proved that high demands can be met with EtherCAT measurement terminals and PC-based control. “The scalable Beckhoff platform offers us the opportunity to handle projects of any size with a standardised system,” says Selg.

In another project, DynoTec used the ELM3602 EtherCAT Terminals to implement one-third octave band analysis of triaxial IEPE vibration sensors with a sampling rate of 50 ksps.

| Tel: | +27 11 795 2898 |

| Fax: | 086 603 6868 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved