Meld Manufacturing has pioneered a solid-state metal additive process that is based on applying friction and force. The advantages compared to melt-based processes include very large-format 3D printers, and higher part strength. For optimal control of its systems, the company relies on flexible EtherCAT and PC-based control technology from Beckhoff.

Launched in 2018, the Virginia-based company offers its capabilities to a wide range of customers in defence, research, and manufacturing. MELD spun off from its parent company, Aeroprobe, in 2018 to apply the principle of friction stir welding to additive manufacturing technologies. Friction stir welding is a method for welding metals without melting them.

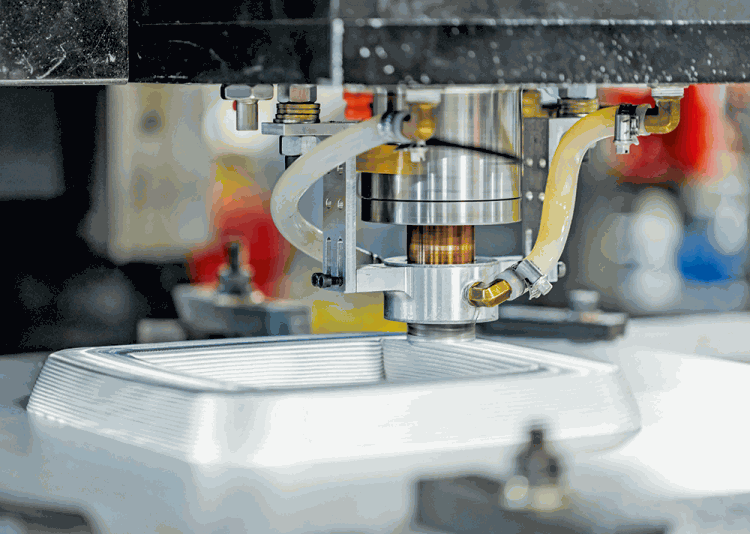

From this, MELD developed an additive process to enable deposition of multiple layers for 3D printing applications. The patented process entails rotating a bar of solid metal while applying a specified force at the point of deposition. Friction causes the metal to deform plasticly and be deposited in a layer. Through adiabatic heating, i.e. without exchanging heat with the environment, the metal feedstock will continue to flow if spun continuously at the correct speed.

The innovative process allows equipment end users to print parts using any metal, including aluminium alloys and others that have typically posed problems for other additive manufacturing systems. As it does not require melting like most other established 3D printing methods, the process also doesn’t affect the metal‘s properties. As a result, the product remains stronger and is less susceptible to porosity, hot-cracking or other typical issues of melt-based additive processes. The solid-state process is also at least 10 times faster and requires less energy.

MELD offers the CD-14 package consisting of a spindle with rotating deposition tool, electrical enclosure and HMI, which machine builders can implement in large, custom systems. Open, scalable control technologies have proven critical to enabling continued development. MELD’s original controls platform could not keep pace. Senior automation engineer, Fred Lalande eventually got in touch with members of the local Beckhoff team. As he learned about fully integrated PC-based control from Beckhoff, Lalande believed he had found the ideal platform for MELD.

What pushed Lalande toward Beckhoff was the TwinCAT 3 automation software. “Previously, I had to use two or three different software packages. That was a pain,” he says. “With TwinCAT, I open one program and everything I need is there.”

As the solutions have developed, the code has grown more sophisticated over time. The portability of code in TwinCAT made it easy to adapt one machine’s program when designing the next. In addition, IP protection is critical in additive manufacturing and especially so with this unique patented process. The Beckhoff software platform gave MELD the ability to lock down its valuable code. Everything is password protected and encrypted, so no one can copy MELD’s developments.

In this 3D process, the spindle speed must be modulated for each specific material to maintain the desired temperature for continuous printing. To accomplish this, the PID controller in the TwinCAT Controller Toolbox provides dual-loop closure on the axis, ensuring successful implementation of MELD’s unrivalled technology.

Motion control and functional safety

The L3, K2 and 3PO machines rely on Beckhoff servo solutions for motion control. A variety of AX5000 servo drives and AM8000 servomotors with appropriate gearboxes handle movement in X, Y and Z coordinates. The drive components also offer One Cable Technology, which combines power and feedback in one cable to simplify commissioning.

A VFD and spindle motor from a third-party spin each machine’s rotating deposition tool, and since the VFD is EtherCAT-based, Lalande found integration to be simple. EtherCAT provided the ease of plug-and-play operation when using devices from both Beckhoff and third parties.

MELD also leverages TwinSAFE, the integrated functional safety solution from Beckhoff. This allows Lalande to implement E-stops, safety doors and TwinSAFE motion functions. “TwinSAFE is straightforward to use,” he says. “By implementing this solution, we elevated the level of safety that our machines provide to PLe, the highest level.”

3D printing grows with futureproof technologies

As MELD continues to make advances in additive manufacturing, PC-based control provides a solid foundation. EtherCAT and OCT shorten commissioning times, while TwinCAT consolidates HMI, motion control, PLC and other machine control functions.

| Tel: | +27 11 795 2898 |

| Fax: | 086 603 6868 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved