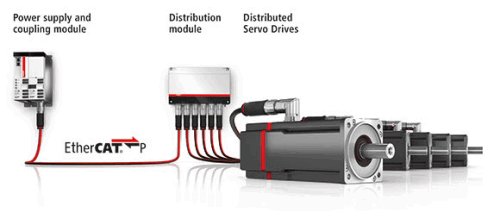

Beckhoff’s AMP8000 distributed Servo Drive system provides ideal support for the implementation of modular machine designs. A servo drive is directly integrated into a servomotor, all in a highly compact design.

In this way, the power electronics are relocated to the machine, reducing space requirements in control cabinets to just a single coupling module. In addition, decentralised distribution modules and the universal EtherCAT P solution further optimise the modular machine design approach.

The AMP8000 system consists of three main components: a single-channel or alternately dual-channel coupling module that forms the starting point, and the only component that still needs to be installed in the control cabinet. The coupling module establishes a connection between the DC link, 24 V DC supply and EtherCAT communication. For use with the high performance AX8000 multi-axis servo system from Beckhoff, the AX883x coupling module is connected to the AX8000 supply module in order to provide a link to the IP 65-rated devices with one or two outputs. In combination with the AX5000 Digital Compact Servo Drive, the AX503x coupling module can also be used in stand-alone mode due to an integrated power supply unit. In this way, 20 A, 600 V DC link voltage, 24 V power supply and EtherCAT networking are available via the EtherCAT P outputs.

This power is initially supplied to an AMP8805 distribution module as a second system component. As an IP 65-rated component integrated into the machine layout, it supplies up to five AMP80xx distributed Servo Drives. It can be mounted either directly (brick style) or using a bracket available as an accessory (book style) and adapted to individual machine designs. The distribution module has an internal capacitance of 1120 µF to support the DC link.

The third system component is the AMP80xx distributed Servo Drive. It is identical to the standard servomotors in the AM8000 series with regard to its mounting dimensions and performance data. Only the overall length has increased in comparison with the standard motors due to the integrated power electronics. Since this added length is not usually critical for the installation, most existing machine designs can be upgraded without the need for modification. The AMP80xx distributed Servo Drives are initially available in the flange sizes F4 and F5. Various versions are available with rated outputs of 0,61 to 1,18 kW and standstill torques of 2,0 to 4,8 Nm (F4) or rated outputs of 1,02 to 1,78 kW and standstill torques of 4,1 to 9,7 Nm (F5). The STO and SS1 safety functions are integrated as standard and a range of extended safe motion functions are currently being prepared.

Universal cabling and cascadable installation

The components in the AMP8000 system are universally connected with the uniform One Cable Automation (OCA) cabling technology, which connects via identical cross-sections and connectors. This is a dynamic, drag-chain compatible EtherCAT P cable with ECP-B23 connectors, which means the one cable solution features a hybrid cable that combines EtherCAT P (communication plus 24 V system and peripheral voltage) with additional power cores. Preassembled cables and connectors facilitate easy installation and minimised errors during cabling.

The AMP8000 system is also cascadable via the distribution module, meaning even highly complex machines and plants can have a simple and clear-cut topology layout. For example, one main distribution module can supply five sub-modules, to which a maximum of 25 distributed servo drives can be connected.

Compact drive integration

With the AMP80xx, the integration of drive technology has been implemented in an exceptionally compact design, made possible through the use of the latest output stage technologies. The power module is attached at the rear end of the servomotor shaft, ensuring that the attachment dimensions are identical to those of the corresponding standard servomotors in the AM8000 series. Only the overall length is about seven centimetres larger. For machine builders, this means only a small amount of additional space is required, making it possible to change their drive concepts without any fundamental design modifications.

Apart from the small overall volume, the elegant and slim design of the AMP80xx offers further advantages. The two dissipated heat sources – motor and power electronics – are clearly separated from each other and ensure much better heat dissipation, without the need for additional installation space or heat sinks. As a result, the distributed servo drives easily attain the same excellent properties as the corresponding standard AM8000 servomotors from Beckhoff.

| Tel: | +27 11 795 2898 |

| Fax: | 086 603 6868 |

| Email: | [email protected] |

| www: | www.beckhoff.com |

| Articles: | More information and articles about Beckhoff Automation |

© Technews Publishing (Pty) Ltd | All Rights Reserved