Miniature servo valves control quadruped robot

3rd Quarter 2015

Editor's Choice

Robotics & Mechatronics

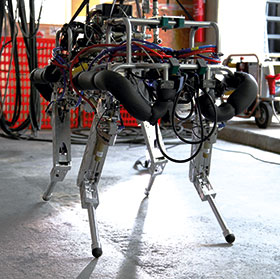

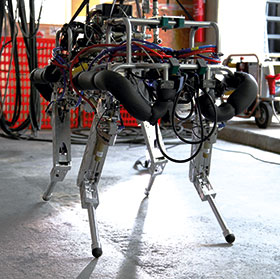

A team of researchers from the Istituto Italiano di Tecnologia (IIT) based in Genova, Italy selected Moog Industrial Group, a designer, manufacturer and integrator of precision control components and systems, to provide a miniature servo valve to optimise control of the legs of a new quadruped robot. The robot called HyQ, or Hydraulically actuated Quadruped, was created to help humans in emergency situations and during search and rescue operations in dangerous areas.

“The project, started in 2007, represents an important innovation in the field of bio-inspired robotics and has the ambitious goal of creating a highly versatile robot capable of moving around on its four legs with agility, even over rough terrains, overcoming the obvious limitations of tracked robots being used up to now,” explains Claudio Semini, project leader engineer at the Advanced Robotics Department of IIT. “For this reason we chose the hydraulic solution for HyQ over the electric one, as it guarantees us higher performance and power, strength and improved control of the legs.”

The design of the ‘actively compliant’ legs was a key element in the development of HyQ because the miniature valve allowed for the rapid modification of the hydraulic flow to the moving parts, enabling modulation of the rigidity/elasticity of the limbs and absorbing the shock of impact when the legs hit the ground, thereby preventing damage to the central body. Moog’s miniature valves fully satisfied the researchers’ need for compact size hydraulic servo valves capable of guaranteeing high performance oil flow control and maximum strength. The E024 series was originally developed for use on F1 automobiles. Its key advantage in motorsport applications is the high power density of the technology in an ultra-light weight design weighing just 92 g.

HyQ represents a complex engineering project made up of mechanical, hydraulic and IT elements and the results to date have been described as remarkable by experts in the industry. This robot can jump or walk on a rocky trail or along a corridor with V-shaped slanted sides, run at different speeds up to 2 m/s and adjust its speed in response to different environments. The installation of a perception system and an inertial measurement unit (IMU) enable the robot to plan its own movements based on a map of the surrounding environment, and correct its steps in real time while always maintaining its pre-determined posture. HyQ is also one of the few robots capable of doing the flying trot, where all four legs lift off the ground. The HyQ can be seen in action at http://tinyurl.com/q7oxl6d

Daniele Masciocchi, sales manager of Moog Italia commented, “Our ongoing cooperation with the Research Team of the IIT for the development of the quadruped robot represents an important best practice and is an indication of Moog’s ability to create specific and highly innovative motion control solutions such as miniaturised systems and components used in various types of industries ranging from robots to Formula 1.”

Claudio Semini, project leader engineer of the Advanced Robotics department of the Istituto Italiano di Tecnologia says: “We are very proud of the enormous progress we have made, but our work is not finished yet. HyQ currently is almost one metre long and weighs about 80 kg. We are still working on the power source system, currently managed through an external unit, in an effort to mount it directly on board, even though it will increase the weight. We are trying to set up new partnerships with companies like Moog that are capable of meeting our needs for components that are smaller and lighter, yet high performance.”

For more information visit www.iit.it/hyq or contact Willie Steyn, Moog, +27 (0)12 653 6768, [email protected], www.moog.com

Further reading:

Planar motor system for quality assurance

Beckhoff Automation

Editor's Choice Electrical switching & drive systems & components

Achieving the shortest possible inspection times, even when working with different components, is paramount when it comes to series production. This is precisely what special machine builder, stoba Sondermaschinen set out to achieve with its InspectorONE optical inspection system, which is based on deep learning and features the Beckhoff XPlanar planar motor system at the conveyor system core.

Read more...

Robotic solution for adhesive tape application with flexible control

Beckhoff Automation

Editor's Choice Robotics & Mechatronics

In industry, even elaborate processes, such as the application of adhesive tape to parts with varying geometries are automated. Innovative Automation has developed a platform with Beckhoff control technology and a remote feeding module, which increases productivity and enables flexible customisation for different requirements.

Read more...

The world’s most powerful worm

Editor's Choice Electrical switching & drive systems & components

Geothermal energy from the natural heat of the Earth is an inexhaustible resource, yet the growth of the global geothermal power sector lags behind other renewable energies. Now Swiss startup, Borobotics is hoping to speed this up with its innovative new electric-powered geothermal drilling robot, which can be used to fast-track and lower the cost of heat pump installations in confined spaces.

Read more...

Problem solving under pressure

Axiom Hydraulics

Editor's Choice

The greatest strength of Axiom Hydraulics lies in the company’s ability to solve complex problems and adapt systems to meet unique challenges. This capability stems from two key factors: the diverse experience of its team members, which spans decades across multiple disciplines, and their unwavering dedication to their clients.

Read more...

New AI advisor for robot selection

igus

Editor's Choice Robotics & Mechatronics

igus’ new AI chatbot has been added to the online platform RBTX.com. The interactive consultant is designed to enable companies with little previous experience and technological expertise to quickly and reliably put together low-cost automation solutions to becoming more competitive.

Read more...

Compressed air treatment do’s and don’ts

Artic Driers International

Editor's Choice Pneumatic systems & components

As a long-established importer and manufacturer of air dryers, Artic Dryers often sees the results of poor installation and issues with aftercoolers that create serious problems in air drying systems.

Read more...

Process control system for the entire plant lifecycle

Siemens South Africa

Editor's Choice

The automation of process plants has been characterised by IT silos for a long time. The high level of IT security required was achieved through strict isolation from the outside world. However, this made unlocking the opportunities for digitalisation very difficult. This is a compelling reason to opt for Simatic PCS neo – Siemens’s completely web-based process control system with state-of-the-art IT security concepts.

Read more...

Celebrating 65 years: rebuilding and redefining its legacy

Axiom Hydraulics

Editor's Choice News & events

Founded in 1959 by Neill Simpson, Axiom Hydraulics has grown into one of South Africa’s elite hydraulic companies. Over the past six and a half decades they’ve weathered many challenges, but none as devastating as the fire of 2023.

Read more...

Monitoring the health of systems

SA Gauge

Editor's Choice Shaft power components

Pressure and temperature gauges are vital instruments in various industries. However, they are susceptible to failures that can compromise their accuracy and reliability. When these gauges fail, the consequences can be severe.

Read more...

PC-based control for advanced hydrogen storage technology

Beckhoff Automation

Editor's Choice Electrical switching & drive systems & components

The proportion of renewable energies from solar, wind and water is rising continuously. However, sufficient storage options are of the essence to use these energies as efficiently as possible. GKN Hydrogen offers a particularly compact and safe option, low-pressure metal hydride hydrogen storage systems with PC-based control from Beckhoff.

Read more...