LS Industrial Systems has launched the LS MV range of medium voltage drives in South Africa catering for the voltage range 3,3 kV–10 kV.

The LS MV medium voltage (MV) drive is a high performance open loop vector control drive for applications between 200 kVA and 11 000 kVA. The drive incorporates advanced features such as automatic power saving, auto-tuning, the ability to synchronise with a heavy rotational mass on the fly, extremely low mains harmonics and a sine-wave output to the motor.

The operating system is identical to that of the popular LS iP5A HVAC VFD, allowing for multimotor pump and fan control without the need for a system PLC.

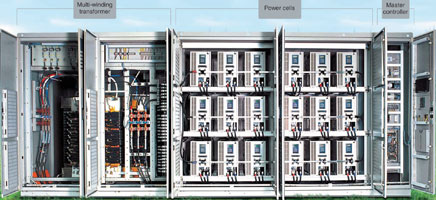

Power cells

The power stages operating on low voltage are made up of unique simple single phase power cells, the number of cells determining the actual drive output power. For instance the 6600 V unit has six cells per phase. The power cells are supplied via a multiwinding transformer with phase difference. The low voltage outputs of the cells are connected in series to provide the MV output. Each cell has its own Cell controller and the cells are synchronised by a Master controller to generate the required three phase output.

The Cell controller controls the PWM of its cell based on commands from the Master controller. As each phase is made up of the sum of the output of multiple cells it is possible to achieve a sinusoidal wave form, eliminating the need for an output filter.

Communication between the master controller and the cell controllers is via a dedicated CAN communications network.

In the event of the failure of a power cell, the drive caters for auto-bypass of the faulty cell. This allows the drive to carry on functioning with only a slightly reduced power output. The bypassed cell can then be wheeled out and replaced during the operation. This design feature reduces the required skill level of the maintenance staff.

Reduced space

Improved airflow through the power stages has enhanced heat dissipation and resulted in a significant reduction in the physical size of the LS MV range.

The output multiphase input transformers are integrally mounted on the LS MV unit at the rear of the drive, further contributing to a space-efficient cabinet design.

Innovative cooling

The speed of the cooling fan is automatically controlled based on the internal temperature of the inverter. This helps to reduce inverter noise levels, saves a little power and extends the life of the fan.

Protection

Like its predecessors, the LS MV has full ground fault protection, even during operation. This feature alone can save thousands of Rands in both maintenance costs and reduced downtime.

Extensive additional diagnostics and protection trips are incorporated in the drive. These include over current, over voltage, over heat, under voltage, CAN communications error, open circuit NTC, and a host of other protective functions.

Interfacing

For system integration the drive is equipped with 24 digital I/O, three analog inputs and four analog outputs, as well as a Modbus 485/Modbus RTU communications interface. Communications options are available for DeviceNet, Profibus-DP, EtherNet-IP, CAN, CANopen and Lonworks.

Optional visualization

The drives also feature a 300 mm (12 inch), 144 colour TFT LCD HMI screen with a wide viewing angle. The screen offers enhanced monitoring and control functionality, with graphical displays of the system performance.

The LS MV is nationally distributed by Ana-Digi Systems.

For more information contact Keith Gross, Ana-Digi Systems, +27 (0)21 914 9030, [email protected], www.anadigi.co.za

| Tel: | +27 11 548 9960 |

| Email: | [email protected] |

| www: | www.profiafrica.co.za |

| Articles: | More information and articles about PI SA (PROFIBUS & PROFINET SA) |

| Tel: | +27 21 914 9030 |

| Email: | [email protected] |

| www: | www.anadigi.co.za |

| Articles: | More information and articles about Ana-Digi Systems |

© Technews Publishing (Pty) Ltd | All Rights Reserved