Mitsubishi Electric is one of the top Variable Speed Drive (VSD) suppliers globally with its wide variety of VSDs that offers the right drive solution for every application.

The biggest consumer of electrical energy can often be pump and fan applications. Conversely these offer the most potential for the largest energy saving opportunities. Therefore, if caution is not exercised when selecting a drive solution, the wrong selection could easily result in the drive using more power than it should.

For example, if full power (50 Hz) is required to produce full flow (water) or volume (air), energy cannot be saved as with constant torque applications. Pump motors absorb 31% energy, fans 23% and conveyors and air compressors 8%.

In the traditional engineering approach fans and pumps are designed with 10% surplus requirements and are often selected from the ‘next higher’ performance curve. Motors are selected then to give 5-10% additional shaft power and most applications use DOL or Star/Delta type starters.

How can a VSD save energy?

A 30 kW application typically absorbs only 25 kW at full load, the difference being wasted energy. Since most flow rates are controlled by dampers or valves, if the speed is reduced by 5 Hz it would result in a 20% energy saving.

For example, when a 15 kW motor is operated at 60% air volume and the power charge is 50 c/kW per hour, the power can be apportioned as follows:

1. Damper control – 15 kW x 0,9 x 0,5 x 24 hours x 365 days = R59 130 p/a.

2. VSD control – 15 kW x 0,3 x 0,5 x 24 hours x 365 days = R19 710 p/a.

Thus (1) – (2) = an energy saving effect of approximately R39 420 p/a.

Many systems require variable flow to meet changing process demands. The two most common methods of controlling variable system output are a control valve or damper and a variable speed drive.

Controlling the flow with a valve or damper fixes the speed of the pump while the valve adds resistance, restricting the output of the system while consuming nearly the same amount of energy. Using a variable speed drive, instead of changing the resistance to modulate flow, the pump speed changes.

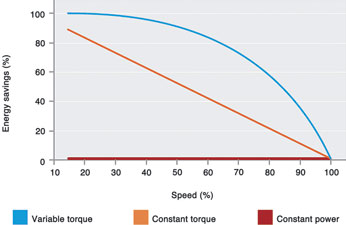

Variable speed control changes the energy input rather than relying on a valve to strip system energy, often resulting in a significant energy saving. Speed reduction results in a more significant energy saving. The larger the flow reduction, the larger the energy saving.

Water industry applications

Variable speed drives enable flow to be controlled efficiently and cost effectively. In the water industry, they are used effectively in the areas of water supply and wastewater treatment. In the water supply environment, these drives are employed in drinking water treatment, water booster systems, weirs, dams and irrigation, seawater desalination systems, swimming pools, industrial water supply, pumped storage power stations and the marine and offshore industry. In the area of wastewater, they play a significant role in effluent treatment and sludge treatment and biogas recovery.

Mining industry applications

With flow rate monitoring, VSDs can be applied to shaft extraction and underground ventilation fans, thus supplying the correct flow at all times. The VSDs would also be suited to pumping water from flooded areas as well as waste water areas. Valves restrict flow, resulting in energy wastage. By utilising the correct drives the need for flow restricting valves are eliminated, resulting in significant energy savings. Water hammer can also be controlled, saving on mechanical damage.

The Mitsubishi FR-F700-EC range

The Mitsubishi FR-F700-EC range of drives has a number of functions that meet the specific needs of water and pumping applications. These functions include a pre-charge function, built-in PLC functionality, expandable I/O and a unit calculator for PID control. These enhancements increase the capability, flexibility and scope of the drives, bringing improved control and reducing the cost and complexity of installation by eliminating the need for additional components.

When employed in the correct manner, variable speed drives will save money when compared to fixed speed motor control.

Some facts about energy saving with variable speed drives:

* The process must have a variable, pressure, flow, temperature, etc.

* Controlling the speed and therefore producing only what is required at the motor shaft to meet the process needs, leads to potentially large energy savings.

* A 10% reduction in speed can give approximately a 27% reduction in energy usage (fan and pump load).

* A 20% reduction in speed can give approximately a 50% reduction in energy usage (fan and pump load).

By setting the VSD to run in variable torque mode, energy savings can be achieved against mechanical damper controls. However, Mitsubishi is able to go further using the ‘energy saving mode’, or for the highest possible efficiency ‘optimum excitation control (OEC)’ can be used.

Energy saving mode

After the output frequency has become constant (acceleration or deceleration is complete), the output voltage is reduced gradually and operation is performed with the output power (product of current and voltage) being minimum. When the output current begins to increase due to the increase in load torque, the output voltage is increased up to the normal V/F pattern to generate the torque required to maintain the speed.

The energy saving effect depends greatly on the magnitude of the load. In applications such as air conditioning equipment, drive operation produces larger energy savings on the running cost than damper control by commercial power supply operation.

Optimum excitation control

OEC is a control method that controls excitation current to improve the motor efficiency and determines the output voltage. This control method converts the motor current to d-q axis to find the excitation current ld and torque current lq, thus obtaining the motor loss by an original method. Motor efficiency can be increased by approximately 15% by the setting of one parameter when OEC is turned on.

Energy saving drive solutions

Efficient pump and fan drive solutions offer the most effective energy saving options for most pump or fan applications. The Mitsubishi FR-F700 range of drives offer optimum features that significantly increases the energy saving capabilities of an application.

* A wide power range from 0,75 up to 630 kW.

* Cost effective due to light duty/super light duty rating.

* Comprehensive communication options.

* Optimum Excitation Control (OEC).

* Energy saving mode.

* Fast energy saving function with the 5 point V/F curve.

* Rated 120-150% overload at 1 Hz.

This energy saving drive solution offers optimal energy savings in applications such as air conditioning systems, fans and blowers, hydraulic systems, compressors, sewage and drains, ground water pumps, heat pumps, drives systems with high idling rates.

In addition to this and various other drive solutions, Adroit Technologies can also offer a full automation solution with its world-class supervisory control and data acquisition software (scada), life-cycle engineering software (MAPS) and alarming and analysis software, which can all be integrated into a Business Intelligence system (Adroit Scada Intelligence) that offers in-depth and detailed reporting. The solutions are designed and engineered for minimum effort, maximum capability and cost effective operation from ground level to the boardroom.

For any more information contact Adroit Technologies, +27 (0)11 658 8100, [email protected], www.adroit.co.za

| Tel: | +27 11 658 8100 |

| Fax: | +27 11 658 8101 |

| Email: | [email protected] |

| www: | www.adroit.co.za |

| Articles: | More information and articles about Adroit Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved