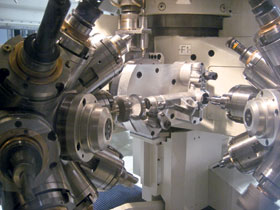

Mouldings are an integral part of modern vehicles. Examples are the multi-layered components of the dashboard, interior trim and seats. To manufacture them, various materials are pressed in special moulds to suit the purpose of the component. The moulds are built as several individual parts that interlock and are essentially the mirror image of the moulding to be produced. They require very high precision in their manufacture as the interlocking of the parts to achieve the sandwich structure of the moulding allows only the tightest of manufacturing tolerances. In addition all surfaces of the mould must be perfectly smooth. Achieving this takes high performance machining centres that machine out the complex geometries to precision by drilling, milling, grinding and polishing – and the rotating union is a critical part of the process.

This is the interface on the fast-turning spindle to the fixed supply lines for cutting fluid, minimum quantity lubricant (MQL), cutting oil or compressed air. The task of the rotating union is to guide these media through the spindle to the tool tip without additional vibration or leakage in the process. Only high quality components can accomplish this effectively.

Modern rotating unions in machining centres are generally based on the balanced seal principle. Two seals run against each other, balanced between opening and closing force by a rotor and stator, where minute quantities of the carried medium lubricate the surface of the seals. Since residual friction is unavoidable, it is reduced to the minimum by ultra-fine lapping of the seals. This increases the service life – an essential quality feature. The seals are permanently closed, hence the name closed seal technology. This system is suitable when only cutting fluid or MQL is run through the machining centre.

However, machining centres for making moulds go further than that. They carry cutting fluid, MQL and cutting oil, are depressurised during tool changes and also do dry working with and without compressed air. Pop-Off technology allows the seals to separate from each other during depressurisation so that no excessive friction and wear occurs. Rotation with compressed air requires a defined microgap between the seal surfaces, which is the exact opposite of closed seal. This is controlled leakage. To automate the switching process, Deublin’s AutoSense series of rotating unions can detect the type of medium and assume the appropriate sealing position automatically.

Combining all these requirements for the machining centre to make high precision moulds calls for an all media rotating union. This gives the machine builder and operator full control over the opening and closing of seal surfaces, allowing them to be disconnected as necessary depending on the media, opening them when carrying compressed air or closing them when carrying cutting fluid, cutting oil or oil mist. This variant is the comprehensive solution for all currently existing media.

Deublin not only provides the machine manufacturer with the components but also offers support, especially when it comes to specific conditions of installation and operation.

When considering the total cost of ownership of a machining centre for making moulds, the cost for investing in highest quality machinery is only part of the story. Also very important are the running costs and costs for service and maintenance over many years of operation. Even though the acquisition may be more expensive, a full system of high quality components pays off quickly and its TCO is lower than a comparable system built from cheaper components.

For more information contact Mike Vernes, PECS, +27 (0)31 303 3701, [email protected], www.pecspower.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved