Manufacturers are under ever increasing pressure to improve the productivity of their machines while decreasing costs. Hydraulics remains the power of choice for heavy duty machinery, but older hydraulic control systems often lack the precision to produce highly accurate and repeatable motion, and high maintenance costs for old machines can further put machine owners at a disadvantage. However new electro-hydraulic control systems are available to empower new machines or give new life to old ones.

Position and pressure/force control

Certain hydraulic equipment, such as presses or injection moulding machines, can benefit from controlling the pressure or force exerted by an actuator in addition to its position. The new generation of electro-hydraulic motion controllers, combined with precise position feedback devices such as magnetostrictive linear displacement transducers (MLDTs), can achieve precise positioning of hydraulic actuators that was not possible before. Methods for controlling position-to-pressure or position-to-force transitions have also advanced significantly.

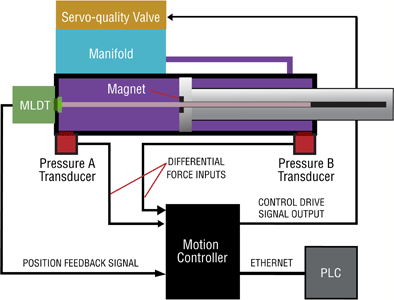

In the past, presses often used pressure relief valves to limit the pressure used to apply force, but there is a flaw in this technique due to net force considerations. Pistons have two sides and a pressure relief valve only reacts to the pressure on one side of the piston. Since there is pressure on both sides of the piston, the applied force is not determined by the pressure on one side of the piston. A better method is to mount pressure transducers on each end of the cylinder as shown below.

The addition of a programmable motion controller able to precisely control applied force and transition smoothly from position control to force control has several advantages:

* Pressure spikes that damage sensors and cause leaks can be reduced or eliminated. This decreases maintenance costs and extends the life of the machine.

* The machine can be adapted automatically to deal with different material consistencies and the effects of differing environmental conditions such as temperature and humidity.

* More flexible production results from the ability to easily change a recipe that changes the positions and forces specified during the machine cycle. Machine downtime for production changeovers can be significantly reduced. Further, target positions and forces can be changed on-the-fly, allowing more flexibility in making the more challenging parts. Several kinds of presses need this capability.

* More consistent, smooth motion results in less wasted or rejected parts, and can ensure consistent production output quality from different machine operators with widely-varying skill levels.

Synchronisation, gearing, and camming

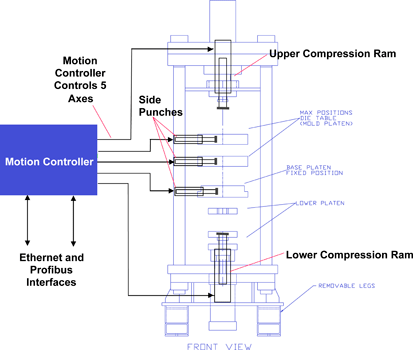

Another distinguishing characteristic of many hydraulic applications is requiring two or more motion axes to move together.

By incorporating a new electro-hydraulic motion controller into a system, the motion of multiple axes can be optimally managed. There are several different ways to link the coordinated motion of one axis to others as the following sections describe.

Synchronisation involves the coordination of multiple axes such that they all move in lock-step. With synchronised motion, position, velocity and acceleration are all being controlled as a function of time. This is critical in hydraulic presses with multiple actuators that must always travel in lock step to prevent binding. The closed-loop motion controller ensures that identical moves are made on multiple actuators.

Key to accuracy of position, velocity and acceleration of synchronised axes is use of a noise free, internally generated target profile for the axes. Synchronised axes must also all be in the same state at all times; they all must accelerate or decelerate together and stop together. In addition, if any axis halts due to a fault, the other axes must halt as well.

Gearing (also called electronic gearing) is similar to synchronisation, where a constant relationship is set up between the motions of two or more axes. While synchronisation uses target positions generated as a function of time, with gearing, the target positions are generated as a function of an external reference or an internal master axis. In the case of an external reference, care must be taken to have a clean signal void of excessive real world problems such as noise, quantisation error and jitter, which can degrade the performance of the geared axes.

Slave axes are geared to the master by specifying that they must do exactly as the master does, except that they must do it according to a specified ratio. For example, if a 2 to 1 ratio is established, the slave will move two inches for each inch the master moves. The gearing ratios can vary and are totally dependent on the requirements of the application.

Hydraulics offers an advantage over mechanically-geared systems for applications where the gear ratios need to be changed on-the-fly. Clutching is the term often used to apply to advanced gearing actions such as this. The goal of clutching is to make a gradual change in gear ratios so the slave axis does not attempt to make abrupt changes in speed.

Managing multiple interrelated motion profiles is not difficult if the right controller is used. The real trick is to find a controller that includes multi-axis synchronisation in its standard offering, preferably as a pre-programmed function. Better yet is a controller that comes with programming tools that allow graphical programming and automated tuning of the motion profile whether linear or rotary. This can save a lot of time in setting up and optimising the system.

Feedforwards

For proper control of multi-axis motion in complex motion systems, it is also advisable to seek out a motion controller that allows the use of feedforward terms in the control algorithm. Feedforwards are predictive elements that allow motion systems to avoid lags due to errors between target and actual position and velocity values. With smaller errors, tighter synchronisation is possible. Motion programmers should set up feedforwards to do most of the control work, with feedback elements (proportional, integral and differential – P, I, and D terms) focused on compensating for nonlinearities and environmental conditions that vary over time. For example, the acceleration feedforward function is useful in compensating for the force required to accelerate the load mass, increasing the control output to the valve during acceleration of the cylinder’s motion. This causes the valve to release more energy into the actuator to make up for the increase in kinetic energy of the load. Some motion controllers come with automated tuning tools that make it easier to tune systems for optimal feedforward and feedback functions.

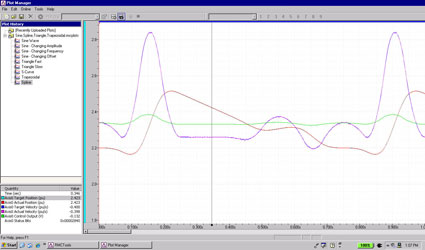

Powerful motion instructions

New motion controllers also support powerful instructions that can make the programming of motion systems easier. For example, hydraulic press applications can benefit from motion controllers that support built-in motion commands that produce complex curving motions. The controllers can do this by interpolating data provided by the user or a host controller. Curves may be programmed to perform either time-based motion, where the curve defines the position of the axis at certain times, or master-based motion, where the curve defines the position of the axis based on a master input, such as the position of another axis.

The ability of the new electro-hydraulic motion controllers to execute cyclic motion profiles make them effective for powering manufacturing test systems that expose production units to realistic forces over a period of hours or days that the products would otherwise encounter over a full lifetime of operation.

Conclusion

Adding closed-loop motion controllers with position-pressure/force control capabilities can make new machines excel or enable older machines to function as well as or better than brand new machines. Smooth motion under position-pressure/force control and synchronisation of axes provide new dimensions of control to increase machine productivity, improve quality and decrease maintenance costs.

For more information go to www.deltamotion.com

© Technews Publishing (Pty) Ltd | All Rights Reserved