Almost any automated equipment, ranging from industrial machines to medical devices, requires components that perform movement in a controlled way. The most common solution to move a load uses electromechanical components such as motors.

Motion control requirements

The most common motors are stepper, brushed, and brushless DC motors, but there are other options. Each motor requires individual input signals to spin the motor and transform electrical energy into mechanical energy. In the broadest sense, motion control helps the engineer to use the motor that best meets the application requirements without dealing with all the low-level signalling needed to spin a motor.

In addition, motion control provides high-level functions which efficiently implement custom applications based on building blocks to create solutions for common tasks such as precise positioning, synchronisation of multiple axes, and movement with defined velocity, acceleration, and deceleration.

Because most of the motors are operated during transient circumstances, motion control tools need to adapt to different loads and dynamic conditions. This requires complex control algorithm processing and feedback information from the mechanical system. Last but not least, motion tasks are usually mission-critical and often operate machines that could harm humans around them. Therefore, security features such as limit switches and I/O channels are required to collect status information and execute shutdown routines.

Motion control system components

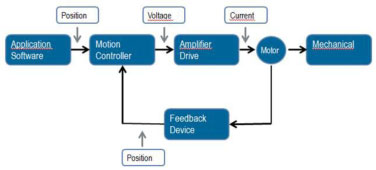

The following diagram illustrates the essential components of a motion control system.

The motion controller is the heart of the motion control system.

The part that is specific to an application is the application software developed by the user. It determines how the motion profile looks and how certain events trigger and influence it. The application software consists of several optional layers. Usually there is a user interface application that offers the possibility of operator interaction. Many motion applications include application layers for alarm handling and database connectivity to link to a SCADA system. They also contain motion control instructions executed by the motion controller. The motion controller manufacturer provides the development environment for the client to create the application software.

With these instructions, the motion controller creates motion profiles. Based on these profiles, the controller sends signals (usually ±10 V or step and direction signals) through an amplifier, or motor drive, to the motor. The amplifier’s job is to take the signals from the controller and change them into signals that cause the motor to move.

As the motor turns, the feedback device – usually a position sensor – delivers position information back to the controller to close the control loop. From this position sensor, the motion controller knows the position of the motor and can derive the velocity at which it is moving. Some applications require multiple feedback devices to ensure that the mechanical system the motors are driving performs the movement the way it should. Although feedback devices offer position feedback, sometimes special feedback information, such as the data from a pressure or vibration sensor, needs to be sent back to the controller.

Motion controller architecture

A motion controller acts as the brain of the motion control system and calculates each commanded move trajectory. Because this task is vital, it requires a dedicated resource that offers a high level of determinism. The motion controller uses the trajectories it calculates to determine the proper torque command to send to the motor amplifier and actually cause motion. The controller also must close the control loop and manage supervisory control by monitoring the limits and emergency stops to ensure safe operation. Each of these operations needs to occur in real time to ensure the high reliability, determinism, stability, and safety necessary to create a working motion control system.

The following list describes the different tasks of a motion controller.

Supervisory control provides the command sequencing and coordination required to carry out specified operations such as:

* System initialisation, which includes homing to a zero position.

* Event handling, which includes electronic gearing, triggering outputs based on position, and updating profiles based on user-defined events.

* Fault detection, which includes stopping moves on a limit switch encounter, safe system reaction to emergency stop or drive faults or watchdog functions.

Trajectory generator provides path planning based on the profile specified by the user.

Control loop performs fast, closed-loop control with simultaneous position, velocity, and trajectory maintenance on one or more axes. The control loop handles closing the position/velocity loop based on feedback, and it defines the response and stability of the system. In stepper systems, a step generation component acts as the control loop. The loop contains an interpolation component, or spline engine, that interpolates between setpoints calculated by the trajectory generator. This enables the control loop to execute faster than the trajectory generator.

Motion I/O serves as the analog and digital I/O that sends and receives signals from the rest of the motion control system. Typically, the analog output is used as a command signal for the drive, and the digital I/O is used for quadrature encoder signals as feedback from the motor. The motion I/O performs position breakpoint and high-speed capture. Also, the supervisory control uses the motion I/O to achieve a specific required functionality, such as reacting to limit switches and creating the movement modes needed to initialise the system.

National Instruments offers two approaches to implement high-performance motion control systems:

* DSP-based plug-in motion controllers for PCI or PXI.

*Custom motion controllers using the National Instruments LabVIEW NI SoftMotion Module.

DSP-based plug-in motion controllers

DSP-based plug-in motion controller

National Instruments provides a variety of plug-in motion controllers that range from high-performance controllers with full-feature capability for sophisticated requirements to lower-cost motion controllers for point-to-point motion applications with solid performance. To enable fast servo update rates of up to 30 kHz for high-precision applications, these controllers use a dual-processor architecture. These two processors, a central processing unit (CPU) and a digital signal processor (DSP), form the backbone of the NI motion controller.

The controller CPU is a 32-bit microcontroller running a multitasking, embedded real-time OS. It offers the performance and determinism needed to meet most complex motion application needs. The CPU performs command execution, host synchronisation, I/O reaction, and system supervision.

The DSP has the primary responsibility of fast, closed-loop control with simultaneous position, velocity, and trajectory maintenance on multiple axes. It also closes the position and velocity loops, and directly commands the torque to the drive or amplifier. Motion I/O occurs in hardware on noncustomisable field-programmable gate arrays (FPGAs) and consists of limit/home switch detection, position breakpoint, and high-speed capture. This ensures very low latencies in the range of hundreds of nanoseconds for breakpoints and high-speed captures.

The motion controller processor is monitored by a watchdog timer, which is hardware you can use to automatically detect software anomalies and reset the processor if any occur. The watchdog timer checks for proper processor operation. If the firmware on the motion controller is unable to process functions within 62 ms, the watchdog timer resets the motion controller and disallows further communications until the motion controller is explicitly reset. This ensures the real-time operation of the motion control system.

These PCI- or PXI-based plug-in motion devices are designed for reliable and precise control within a Windows or real-time OS. They provide reduced development time through powerful APIs and support within interactive tools such as the NI Motion Assistant. The highest-performance National Instruments motion controller family is the NI 7350 Series, which offers up to eight axes of stepper or servo motion control, extra I/O, and many powerful features including sinusoidal commutation for brushless motors and 4 MHz periodic breakpoints or position triggers for high-speed integration. Because these plug-in motion controller devices are based on PCI or PXI, they can be integrated with a wide variety of additional I/O modules and easily combined with additional hardware for data acquisition or image processing. To connect the motion control devices to drives and motors, NI provides several cabling and connector block options.

Custom motion controllers

While plug-in motion controllers with DSPs are suitable for many applications, customised motion controllers are needed for high-precision motion control, with servo update rates as fast as 200 kHz. Applications that require such a high level of precision and flexibility include wafer processing machines in the semiconductor industry or the inline vehicle sequencing (ILVS) reconfigurable-at-run-time assembly lines for the automotive industry.

National Instruments’ reconfigurable I/O (RIO) technology combined with NI SoftMotion technology provides the right tools for machine builders who want high-precision customised motion control with the flexibility of an FPGA. In addition to high-precision applications, machine builders and OEMs can use the LabVIEW NI SoftMotion Module to implement multi-axis coordinated motion control using the LabVIEW graphical development environment on a variety of platforms. For applications that require rugged and compact systems, NI CompactRIO programmable automation controllers (PACs) can be used. By combining the

high-level function block API of LabVIEW NI SoftMotion and new NI C Series drive interfaces, powerful motion applications can quickly be developed and connected to hundreds of stepper and servo drives.

For more information visit http://zone.ni.com/devzone/cda/tut/p/id/9667 or contact National Instruments, +27 (0)11 805 8197, [email protected], www.ni.com/southafrica

© Technews Publishing (Pty) Ltd | All Rights Reserved